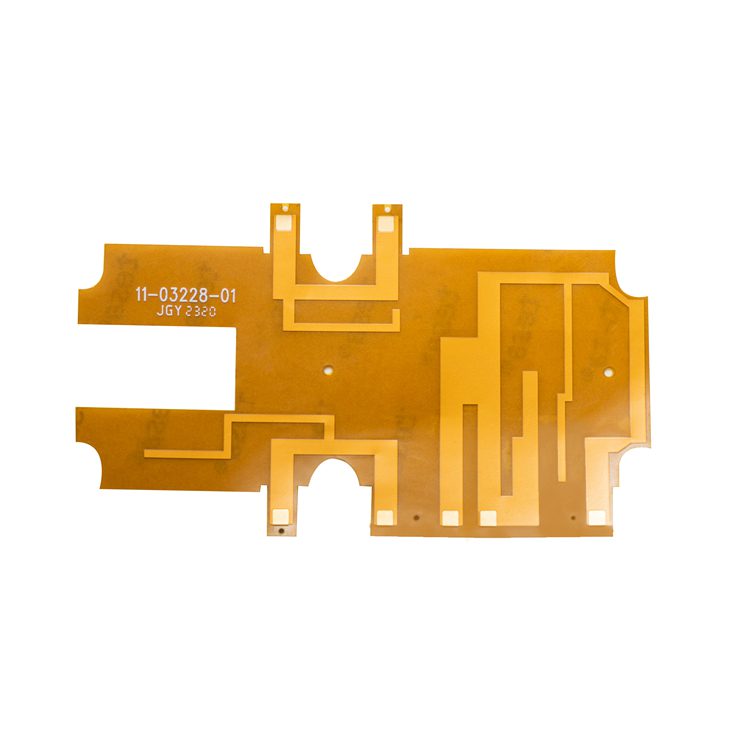

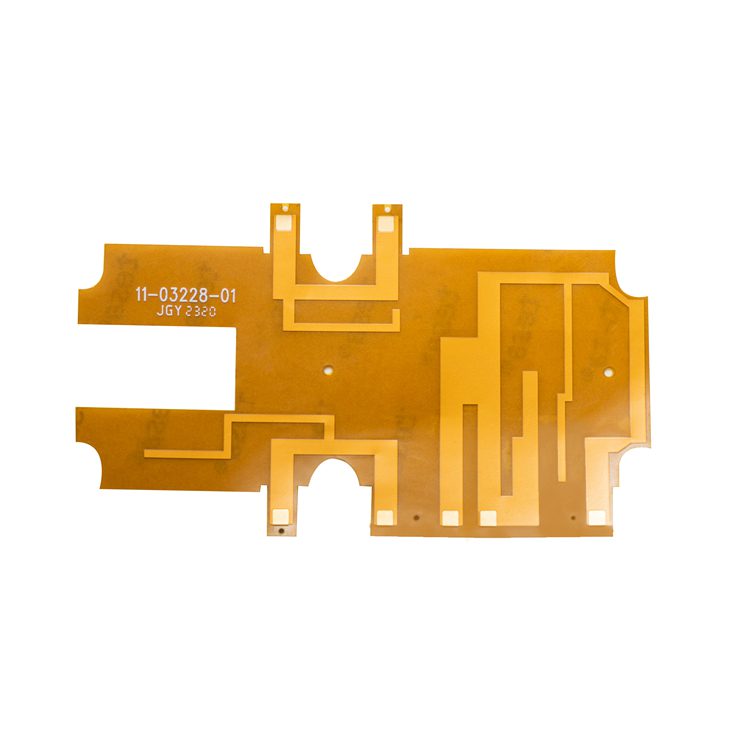

FPC (Flexible Printed Circuit) has been widely used as a flexible and foldable circuit board. Its application in electronic products is becoming increasingly widespread, but there are also some difficulties and bottlenecks in the sampling process of FPC flexible circuit boards. The traditional sampling process often takes a long time, is costly, and has low production efficiency. We propose a process innovation method to address these issues, which can effectively solve the problem of sampling FPC flexible circuit boards.

Firstly, we have introduced advanced CAD/CAM software technology.

Using CAD software for circuit design and layout can visually present the structure and routing of the circuit board. Meanwhile, CAM software can convert circuit diagrams into actual machining paths, achieving efficient automated production. In this way, not only can production efficiency be greatly improved, but errors and losses can also be reduced, and the accuracy and quality of products can be improved.

Secondly, we have adopted more advanced materials and processes.

Traditional FPC flexible circuit boards often use polyimide (PI) as the substrate, but this material has characteristics such as high temperature resistance and flame retardancy, but its flexibility is relatively poor. Therefore, we have chosen a new type of polymer elastomer material as the substrate, which can better adapt to the folding and bending needs of FPC. At the same time, we have also adopted a more advanced pre coated film molding process, making the manufacturing process of the circuit board smoother and more efficient.

In addition, we have also introduced 3D printing technology.

In the traditional FPC flexible circuit board sampling process, expensive and complex molds are often required to be made. 3D printing technology can directly produce solid models based on CAD designed models, greatly simplifying the mold production process while also saving costs and time.

In summary, our process innovation method has successfully overcome the challenges of FPC flexible circuit board sampling by introducing advanced CAD/CAM software technology, adopting new materials and processes, and applying 3D printing technology. This method not only improves production efficiency and product quality, but also reduces costs, bringing greater convenience to the manufacturing and application of FPC flexible circuit boards.