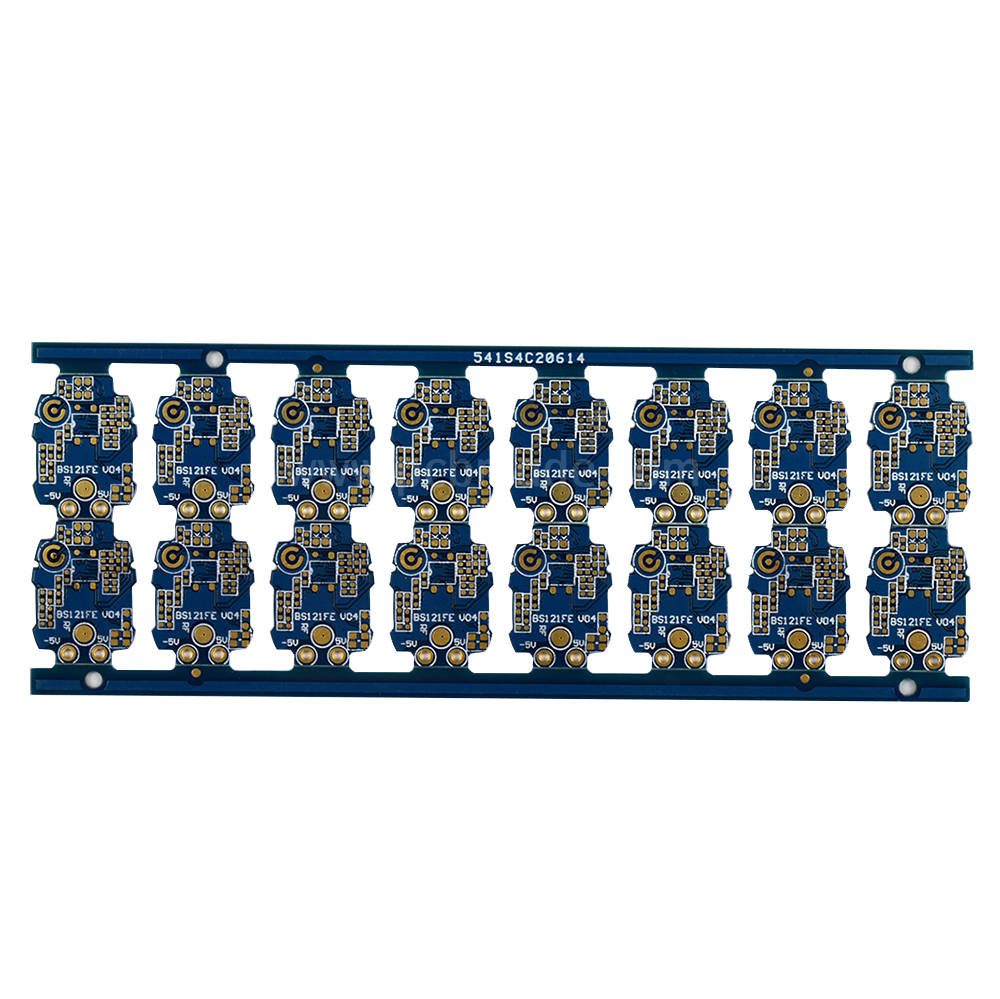

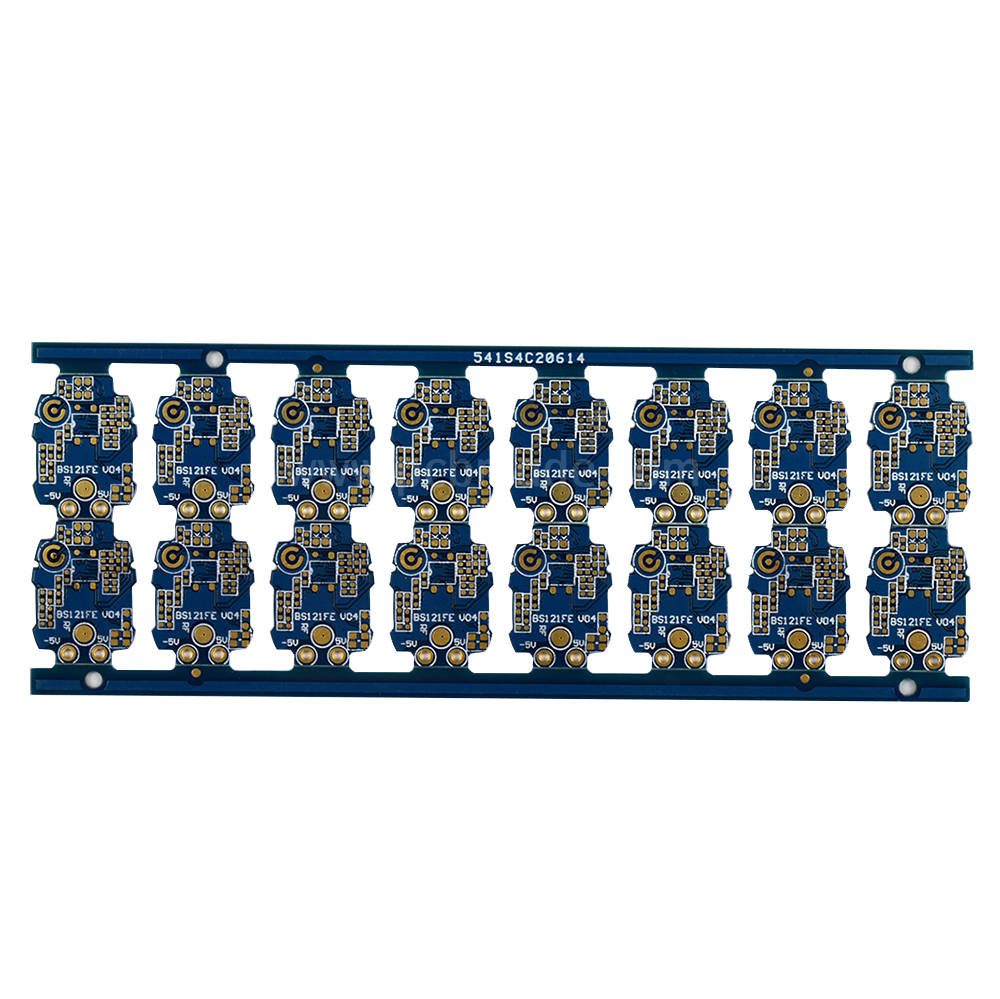

Electromagnetic interference (EMI) refers to the impact of electromagnetic radiation or induction on the normal operation of electronic devices. In the development of modern industry, circuit boards, as one of the core components of electronic devices, often face the threat of electromagnetic interference. Today, Huihe editor will introduce the impact of electromagnetic interference on circuit boards and provide some protective measures to ensure the normal operation of circuit boards.

一、 The impact of electromagnetic interference on circuit boards

Electromagnetic interference may have the following adverse effects on circuit boards:

1. Signal distortion: Electromagnetic interference can cause waveform distortion of current and voltage, thereby affecting the quality and accuracy of signal transmission on the circuit board.

2. Increased error: Electromagnetic interference may cause sensors on the circuit board to erroneously sense external interference signals, thereby increasing measurement errors.

3. Component damage: Electromagnetic interference can interfere with the components on the circuit board, which may cause damage to electronic components and even lead to dangerous situations such as short circuits and fires on the circuit board.

二、 Protective measures

To prevent electromagnetic interference from affecting the circuit board, we can take the following protective measures:

1. Ensure good grounding: Good grounding is an effective means of reducing electromagnetic interference. By designing and arranging the grounding system reasonably, the transmission rate and amplitude of interference signals can be reduced, and the impact on the circuit board can be minimized.

2. Use shielding materials: When designing and manufacturing circuit boards, shielding materials can be used to isolate electromagnetic radiation and induction. Common shielding materials include aluminum foil, copper foil, and shielding covers.

3. Strengthen filtering design: In the process of circuit board design, filtering circuits should be reasonably set up to reduce high-frequency noise and interference signals on transmission lines.

4. Reasonable layout of power and signal lines: Reasonable layout of power and signal lines can reduce the possibility of electromagnetic radiation and induction. Mutual crossing and proximity to sensitive components should be avoided.

5. Use shielding covers and shielding holes: If necessary, shielding covers and shielding holes can be added to the circuit board to isolate and absorb external electromagnetic interference.

6. Testing and Inspection: During the manufacturing process, it is necessary to test and inspect the circuit board to ensure its ability to resist electromagnetic interference. Methods such as Electromagnetic Compatibility (EMC) testing can be used.

In short, the impact of electromagnetic interference on circuit boards cannot be ignored, and corresponding protective measures must be taken to reduce its impact on circuit boards. By using good grounding, shielding materials, and reasonable layout, the impact of electromagnetic interference on circuit boards can be effectively reduced, ensuring their normal operation and reliability.