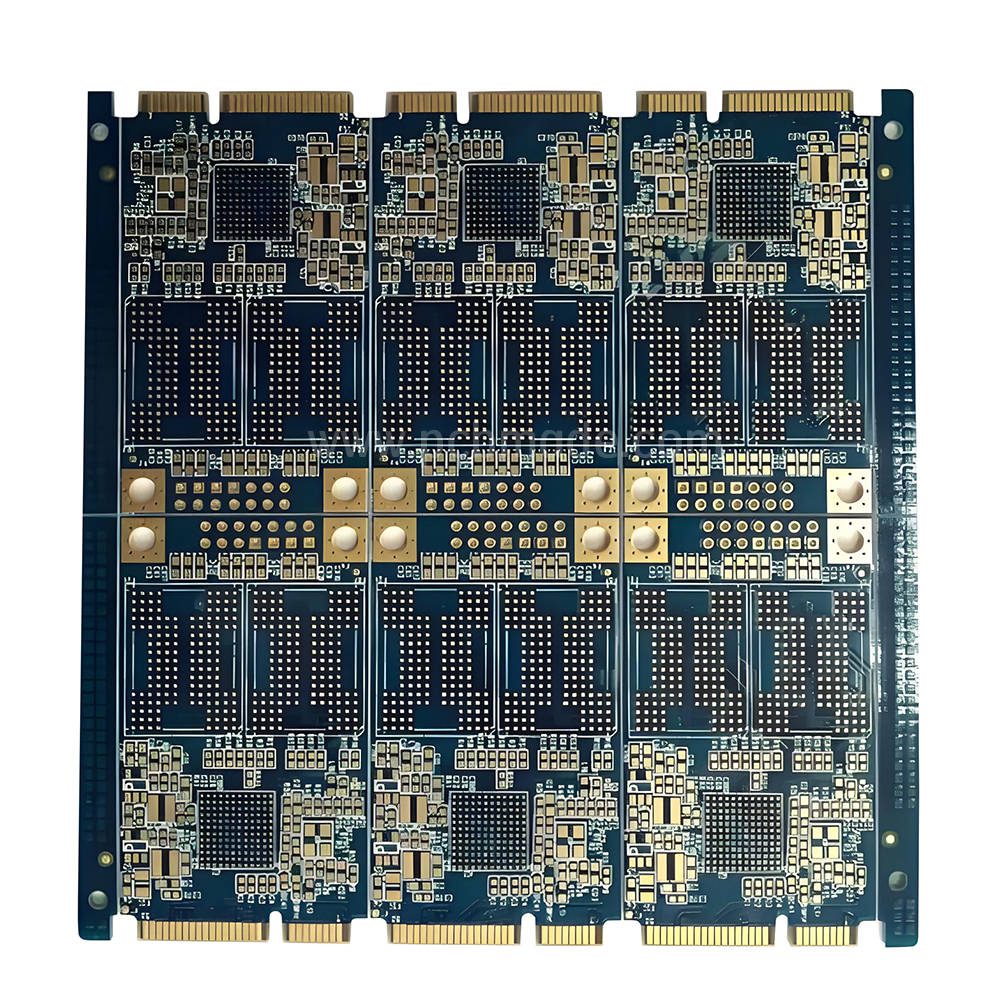

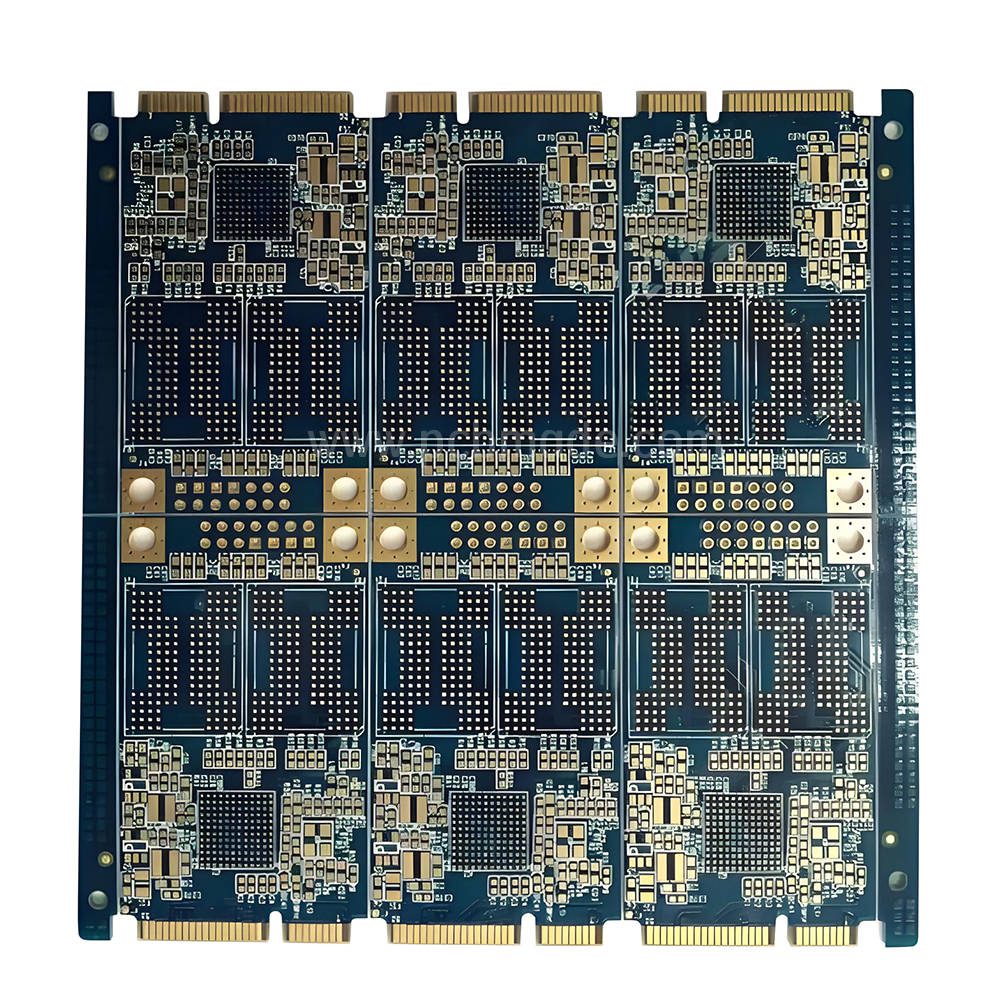

With the acceleration of urbanization, rail transit plays an increasingly important role in the modern transportation system. As a high-capacity, high-efficiency, and low-carbon transportation tool, the safety and efficiency of rail transit have become the focus of people’s attention. As an important component of the rail transit system, the PCB board for rail transit control has some key characteristics that can improve the safety of the system and optimize operational efficiency.

Firstly, PCB boards have excellent reliability and stability in rail transit control systems.

The rail transit system is a highly automated system, therefore its key components must have excellent reliability and stability to ensure long-term stable operation of the system. As the core of the control system, the PCB board undertakes important functions such as signal transmission and power transfer, and must be able to operate for a long time without failure. Therefore, selecting high-quality PCB board materials and implementing precise manufacturing processes are key to ensuring system reliability and stability.

Secondly, the wiring design of PCB boards is crucial for the performance of rail transit control systems.

Reasonable wiring design can reduce electromagnetic interference, improve signal quality, and thus reduce system noise and errors. In the control system of rail transit, signal transmission is a key link. If the wiring of the PCB board is not reasonable, problems such as signal attenuation and cross interference are likely to occur, leading to a decrease in system performance or even malfunctions. Therefore, in the design process of PCB boards, it is necessary to fully consider factors such as the direction, length, and spacing of signal transmission lines to ensure fast and stable signal transmission.

In addition, PCB boards also need to have good thermal management capabilities.

In the rail transit system, due to the long-term operation and frequent start stop of vehicles, a large amount of heat is generated. If the heat dissipation of the PCB board is poor, it is easy to cause the temperature of the components to be too high, thereby affecting the stability and lifespan of the system. Therefore, in the design process of PCB board, it is necessary to arrange the position and quantity of heat dissipation devices reasonably, optimize the heat dissipation structure, improve the efficiency of heat conduction and dissipation, and ensure that the system can work stably for a long time in high temperature environment.

In addition, PCB boards also need to have protective measures to cope with unpredictable harsh environments.

During the operation of rail transit, various harsh environmental conditions may be encountered, such as severe cold, high temperature, and high humidity. If the PCB board cannot effectively resist the invasion of these unfavorable environments, it is easy to cause system failures, which in turn affect the operation of the entire rail transit. Therefore, in the design and manufacturing process of PCB boards, it is necessary to select suitable protective materials and coatings to increase their ability to withstand harsh environments, and conduct strict reliability testing to ensure that the system can work properly under various harsh conditions.

In summary, the key characteristics of PCB boards for rail transit control include reliability and stability, optimized wiring design, good thermal management capabilities, and protective measures to adapt to harsh environments. The comprehensive effect of these characteristics can not only improve the safety of the rail transit system, ensure the safety and comfort of passengers riding on the rail transit, but also optimize the operational efficiency of the system and improve transportation capacity. In the future, in the development of rail transit, the key characteristics of rail transit control PCB boards will continue to improve, providing people with a safer, more convenient, and efficient way of transportation.