If you need to design a circuit board, then you need to make a PCB sample for it. However, how to determine the quantity and specifications of PCB samples is a topic worth exploring. Below, this article will share how to determine the quantity and specifications of PCB samples based on your needs, in order to better meet your requirements.

1. Determine the quantity of PCB samples based on project requirements

When determining the quantity of PCB samples, the first thing to consider is the project requirements. For example, if you only need one PCB to make, then making a sample is enough. But if you need to produce a large number of PCBs, such as thousands or more, then you need to make several more samples for testing or produce them in larger quantities.

In addition, it should be noted that if your circuit board requires extensive pre-processing or special processing, it is also necessary to make multiple samples. Because if there are problems during processing, it will waste a lot of time and manpower.

In addition, if your project requires modifications, testing, and other operations during the development process, you also need to create more templates to facilitate quick modifications and testing.

2. Determine the specifications for PCB sampling based on the design specifications

In addition to quantity, determining the specifications for PCB sampling is also very important. Especially when designing complex circuit boards, customizing specifications according to requirements will bring convenience to subsequent testing and production. The following are specific elements:

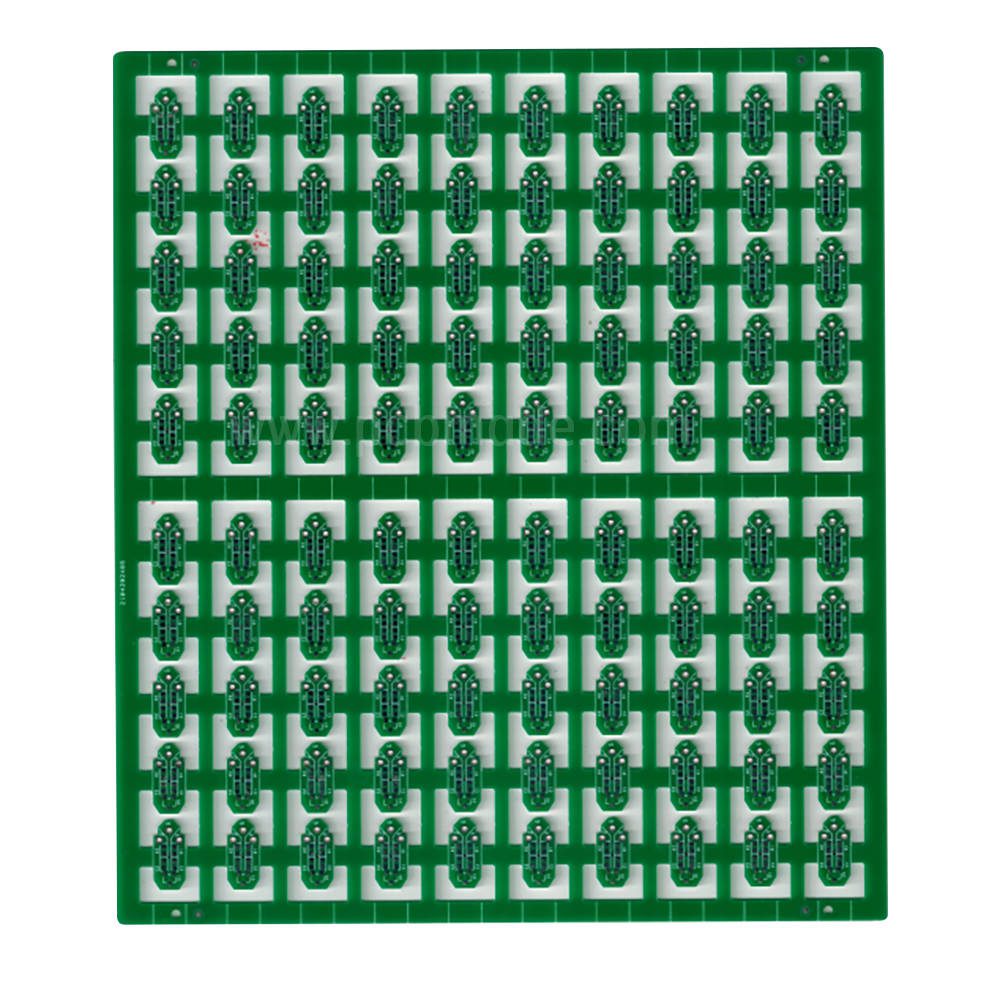

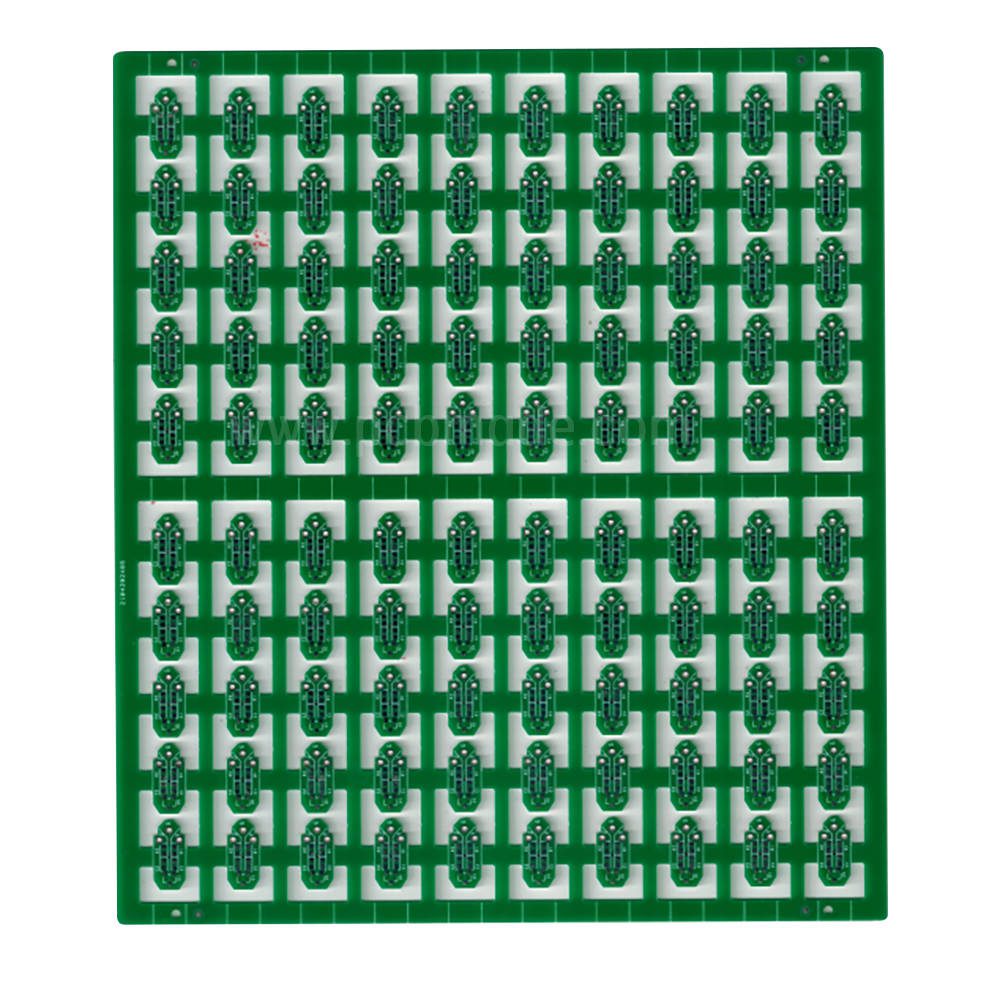

The external dimensions of the circuit board: The size of the PCB is determined based on the required external dimensions for convenient operation in storage, transportation, installation, and other aspects.

The number of layers and network structure of PCB: Determine the number of layers of PCB as needed, such as single-sided, double-sided, multi-layer, etc., and design a reasonable layout diagram for the network structure.

Design circuit diagram: Determine the number of pins, position distance, etc. of the circuit board based on the required circuit diagram to achieve working effect and quality in subsequent installation and use.

Component size: Define the device installation area and spacing of the PCB based on the component size for placement and debugging.

Material and thickness: Select high-quality materials such as FR-4 as needed to ensure the quality of the PCB. In addition, determining the thickness of the board is also very important to ensure PCB strength, wear resistance, and heat transfer capability.

How to determine the quantity and specifications of PCB samples based on requirements is a very important step in designing circuit boards. It is necessary to conduct detailed thinking and planning to ensure that the expected goals and effects are achieved in subsequent operations. If you need help, you can consult a professional PCB sampling factory.