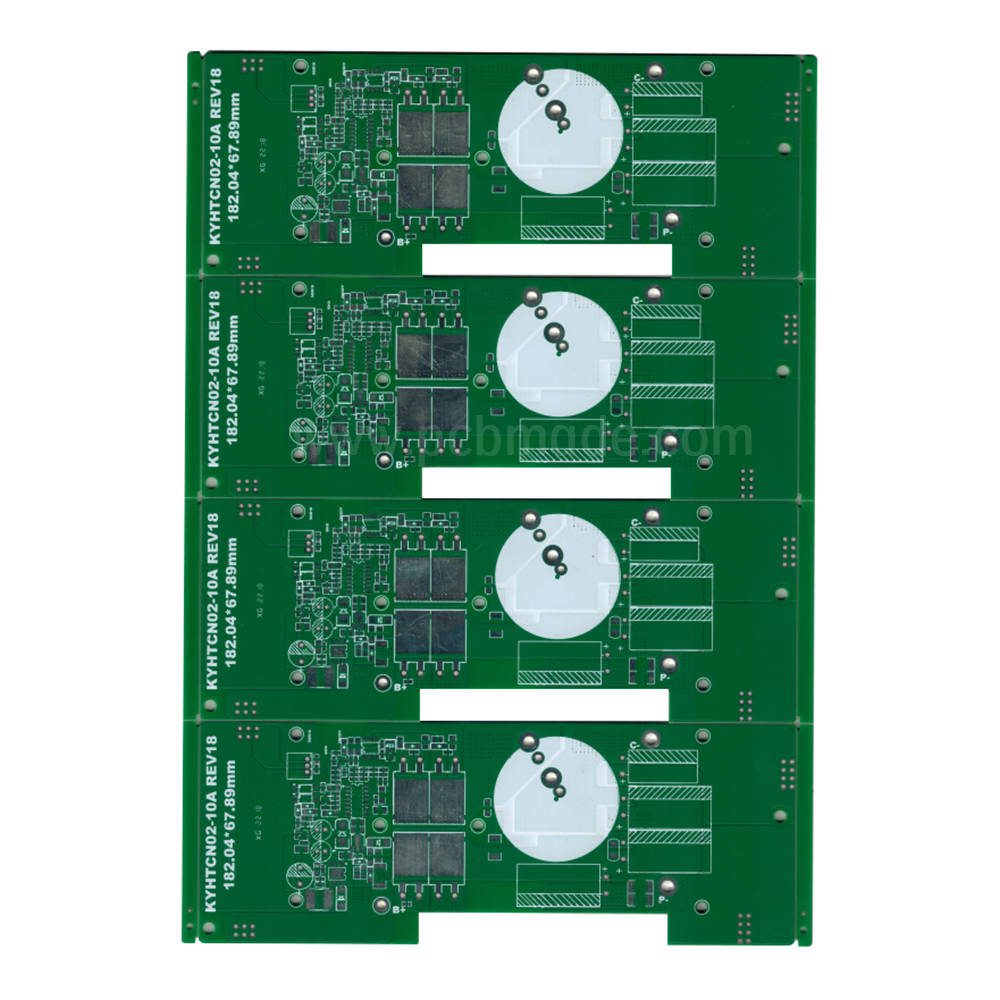

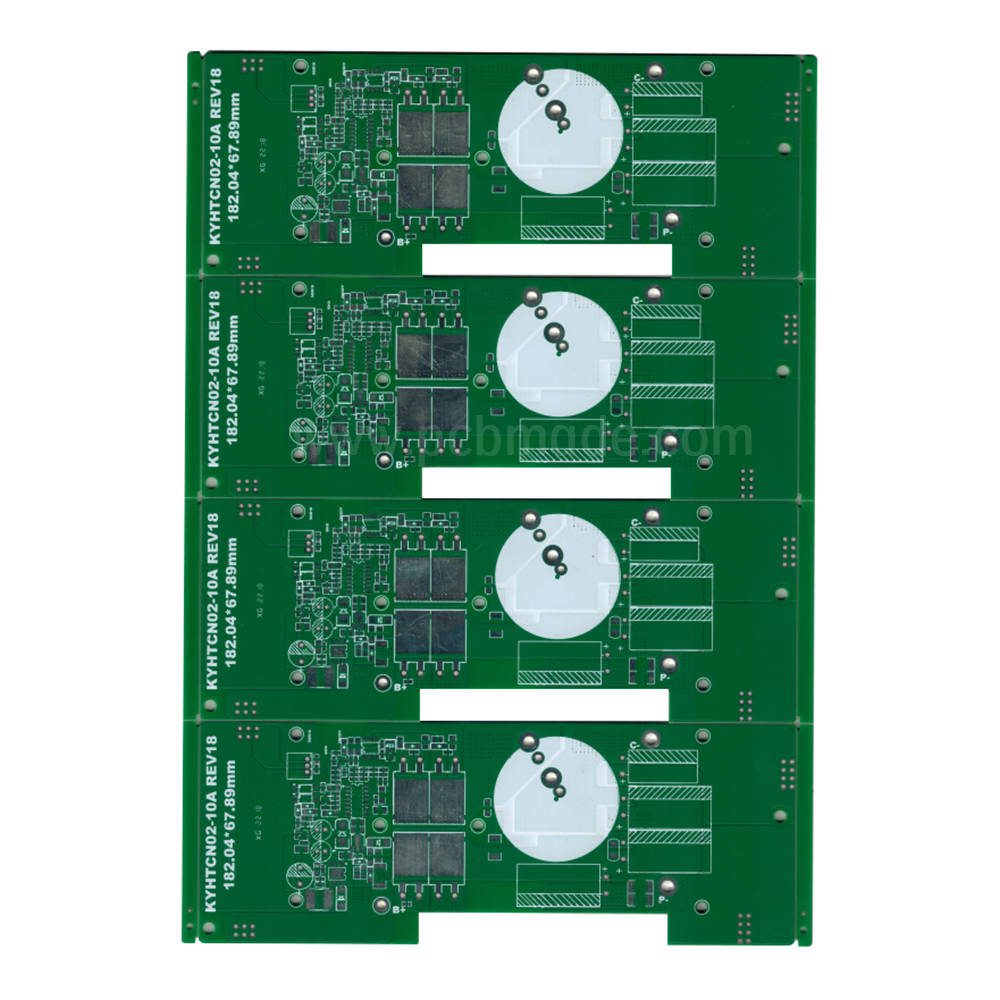

With the continuous development of electronic manufacturing technology, PCB (Printed Circuit Board) has become an indispensable and important component in electronic manufacturing. In the PCB manufacturing process, panel assembly technology is a crucial step. The correct splicing technique can greatly improve manufacturing efficiency and quality. So how to correctly assemble PCB boards?

一、 Splicing rules

1. Try to assemble components of the same size and packaging together to reduce gaps on the board.

The spacing between components should be large enough to facilitate subsequent assembly and maintenance, as well as ensure electrical isolation between components.

3. Strictly follow the device design diagram to assemble the board, ensuring correct electrical connections, especially the accurate connection of power and ground wires, to avoid problems such as short circuits.

4. Try to minimize the distance between components and metal edges to reduce electromagnetic interference between components and edges.

5. Avoid crossing between components and reduce interference.

二、 Splicing method

1. Manual panel assembly

Manual splicing is usually used for simple circuit boards. For larger scale and component intensive circuit boards, manual splicing has lower efficiency and is prone to errors.

2. Automatic panel assembly

Automatic panel assembly is usually carried out by machines, which can quickly and automatically assemble components together, greatly improving work efficiency. Automatic splicing requires writing splicing rules to ensure the correctness and standardization of splicing.

3. Mixed splicing board

Mixed splicing is a combination of manual splicing and automatic splicing, usually first using a machine to automatically splice and then manually fine-tuning to ensure the accuracy and efficiency of the circuit board.

In short, when conducting PCB assembly, it is necessary to follow the assembly rules, adopt reasonable assembly methods, and fully utilize the functions of schematic software and PCB design software to improve work efficiency and reduce errors.