The SMT of a circuit board (PCB) is a crucial step in the electronic manufacturing process, involving the precise placement of various electronic components on the board to ensure the normal operation of the circuit. In the industry, SMT, also known as Surface Mount Technology, is a circuit assembly technology that involves mounting electronic components on the surface of a circuit board or other substrate, and assembling them through methods such as reflow soldering or immersion soldering.

With the increasing complexity of electronic products, PCB manufacturing and mounting technology has evolved from simple single-sided mounting to double-sided mounting and high multi-layer board mounting processes, which puts higher demands on mounting processes and equipment, especially in terms of accuracy, temperature control, and production line efficiency. This article will provide a detailed introduction to the complete process, key process points, and precautions for circuit board mounting.

The basic process of circuit board mounting

Generally speaking, there are several steps involved in circuit board mounting:

1. Printing solder paste

Printing solder paste is the first step in circuit board mounting. Solder paste is composed of tiny tin powder particles and flux, which can melt and form conductive connections during reflow soldering. Before the SMT process begins, the manufacturer needs to evenly print solder paste on the solder pads of the circuit board, and the accuracy of this step directly affects the subsequent mounting effect.

Key points:

Ensure even distribution of solder paste to avoid empty solder joints or short circuits between components and solder pads.

Use high-quality templates and precision printing equipment to ensure printing accuracy.

Regularly check the viscosity and freshness of solder paste to avoid a decrease in solder paste performance due to prolonged use.

2. Component mounting

After completing the solder paste printing, the surface mount machine will automatically accurately place the surface mount components (SMD) onto the solder pads printed with solder paste. Modern surface mount machines have extremely high mounting speed and accuracy, capable of handling everything from tiny resistors and capacitors to complex integrated circuits.

Key points:

Accurate mounting position is a prerequisite for ensuring the normal operation of the circuit, and calibration and debugging of the surface mount machine are crucial.

Choosing surface mount equipment with high precision and speed can improve production efficiency and reduce rework rates.

3. Reflow soldering

After the component placement is completed, the circuit board is soldered through a reflow oven. The soldering furnace gradually heats the circuit board to the melting point of the solder paste, causing the solder paste to melt and firmly connect the components to the PCB pads. Reflow soldering is a key step in ensuring the firmness and electrical connection performance of the patch.

The temperature curve setting for reflow soldering should be optimized according to the type of component and the material of the circuit board to avoid overheating or insufficient soldering that may result in weak soldering or component damage.

4. Quality inspection

After reflow soldering is completed, a series of quality checks need to be conducted on the circuit board to ensure that each component has been correctly installed and soldered securely. Common detection methods include AOI (Automatic Optical Inspection), X-ray inspection, and functional testing.

AOI can quickly detect the quality of component mounting and soldering, especially the integrity and position of solder joints.

X-ray inspection is suitable for multi-layer boards and can check the welding quality inside to ensure that there are no bubbles, poor solder joints, or other issues.

Functional testing verifies whether the circuit board can function properly, including electrical performance, component functionality, and signal transmission.

Precautions for SMT of circuit boards

During the process of circuit board placement, factors such as environment, equipment, and materials can all have an impact on the quality of the final product. Here are some key points that need special attention in the SMT process:

1. Environmental control

The SMT workshop should maintain a constant temperature and humidity to prevent solder paste from getting damp or components from being damaged by static electricity. Generally speaking, the temperature should be controlled between 22-26 degrees Celsius and the humidity between 40-60%. Excessive or insufficient temperature and humidity can affect the performance of solder paste, thereby affecting the quality of surface mount.

2. Equipment maintenance

Regular maintenance and calibration of equipment such as SMT machines and solder paste printing machines are necessary steps to ensure SMT accuracy. Unstable operation or decreased accuracy of the equipment can lead to issues such as component displacement and poor soldering, directly affecting the performance and lifespan of the circuit board.

3. Select high-quality materials

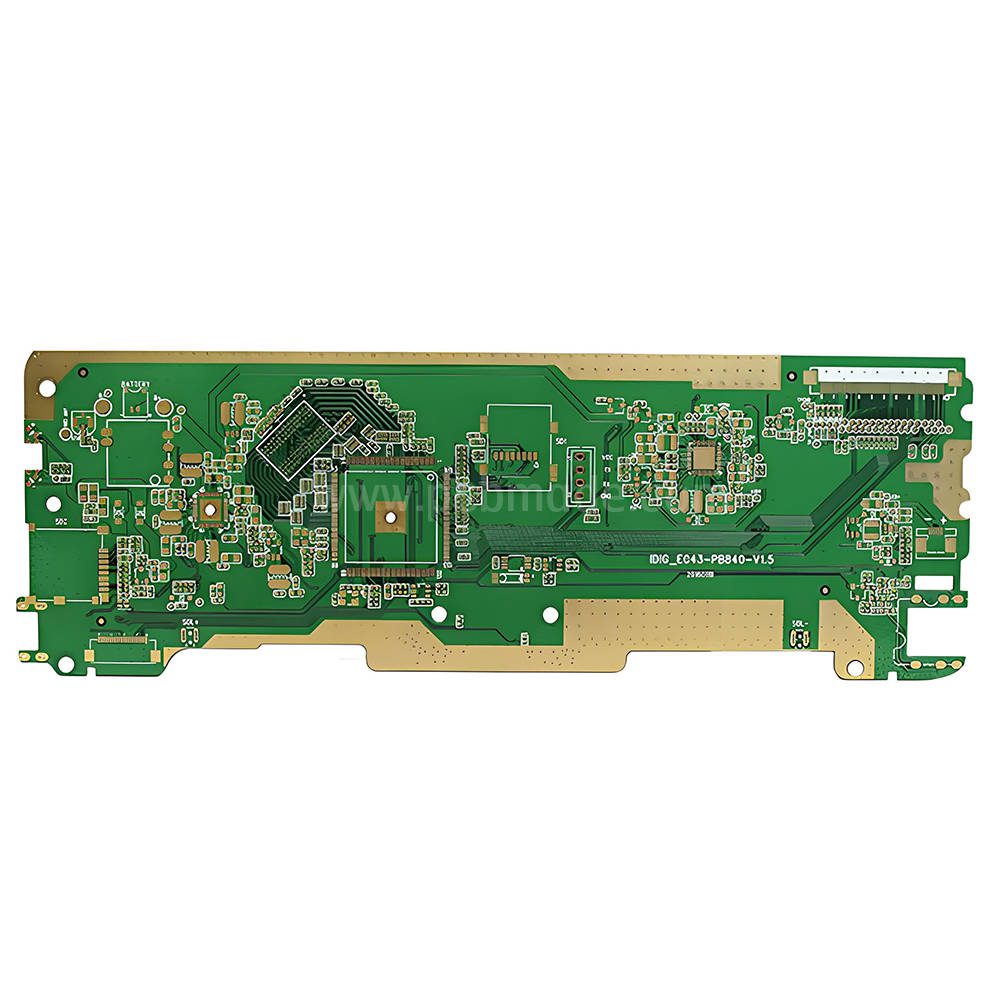

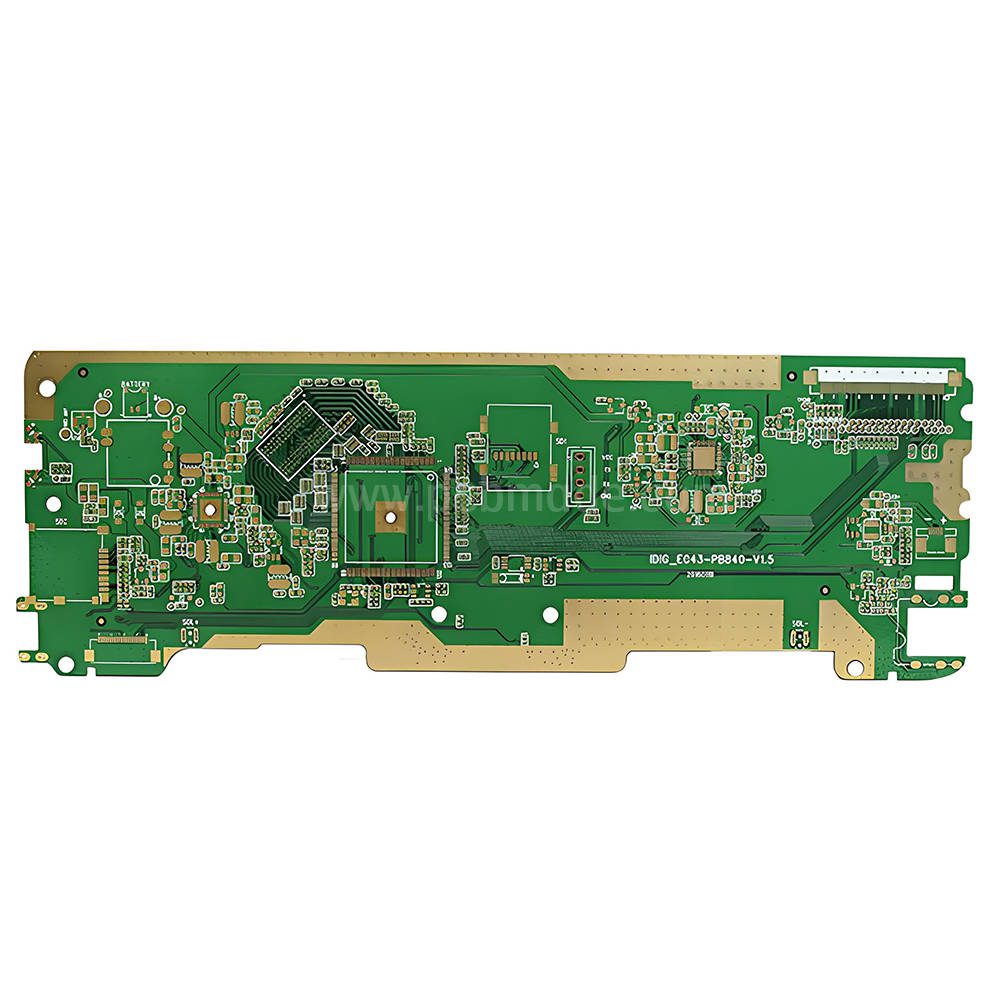

High quality solder paste, components, and PCB boards are the foundation for ensuring the success of the SMT process. High quality solder paste has good fluidity and conductivity, which can form a strong connection during high-temperature reflow soldering. In addition to solder paste, PCB boards are also very important. Like Jialichuang PCB, the multi-layer and 6-layer boards use Jiantao and China South Asia boards, with high quality and guarantee. Because Jiantao board uses high-quality FR-4 as the substrate, high-purity copper foil as the conductive layer, and undergoes strict processing, it has the characteristics of high quality and good performance and is widely used in the electronics industry.

For 8-layer boards and higher floors, Jialichuang uses Taiwan, China Nanya Hesheng boards. Among them, as a well-known domestic supplier of copper-clad laminates, Shengyi Plate has the characteristics of high standards, high quality, high performance, and high reliability, with high industry recognition. It is widely used in electronic products such as industrial control, medical instruments/devices, consumer electronics, and automobiles.

The process of circuit board mounting is a key link in modern electronic product manufacturing, from solder paste printing, component mounting, reflow soldering to quality inspection, every step is crucial. By understanding these processes, electronic engineers can better optimize designs and improve product quality.