In the vast ecosystem of electronic manufacturing, PCB prototyping is like the mainspring of a precision clock, serving as both the starting point for product development and the touchstone for technology implementation. One late night, an engineer was staring at the circuit design on the screen, and his team needed to complete the verification of the smart bracelet motherboard within three days. At this moment, every wire on the circuit board carries the time window for product launch, and choosing which PCB prototype manufacturer to use has become the sword of Damocles hanging over the team’s head.

There is a real case circulating in the industry: a medical equipment manufacturer experienced signal crosstalk in a high-frequency environment due to a line width deviation of 0.02 millimeters during sampling. It’s like under the carving knife of a micro sculptor, an extra tremor can make the entire piece lose its soul. Top PCB manufacturers use a six axis automatic optical detector to perform 3D scanning on each board, with hole copper thickness controlled between 20-25 microns. This obsession with details allows the circuit board to maintain stable impedance values even in extreme temperature testing. As industry veterans often say, “The copper foil on the circuit board speaks, and every square inch is a technical declaration

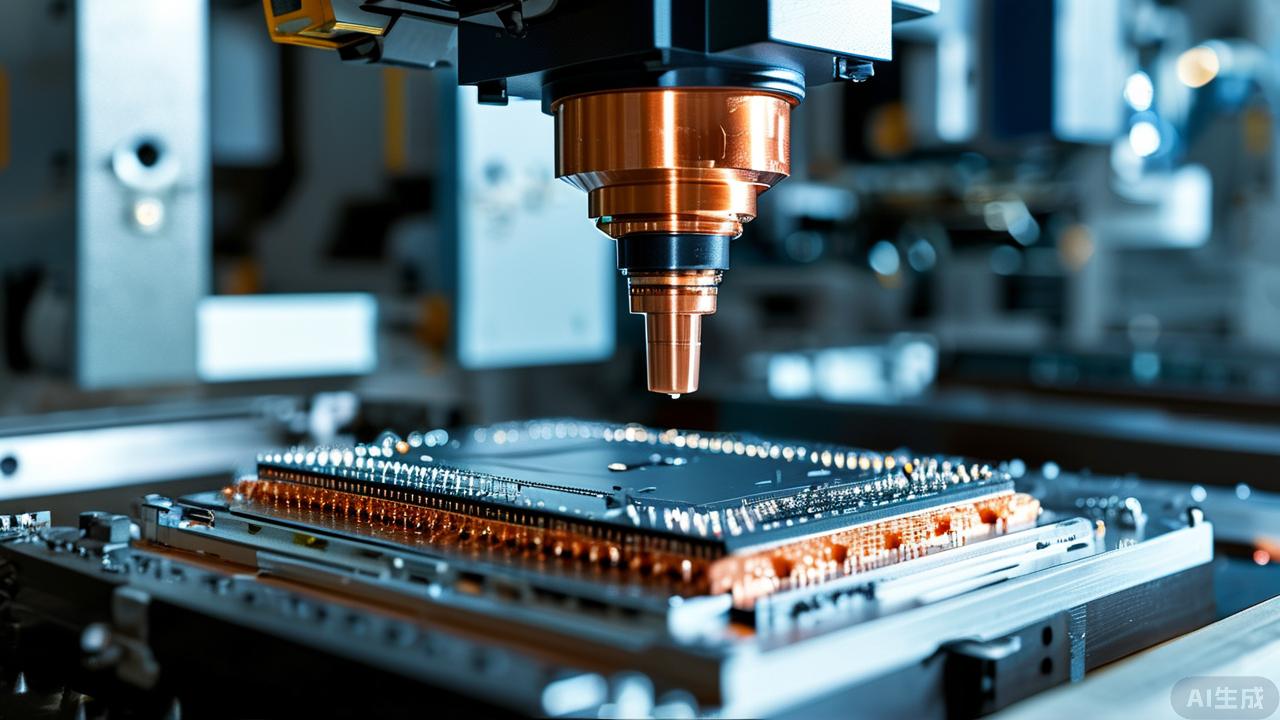

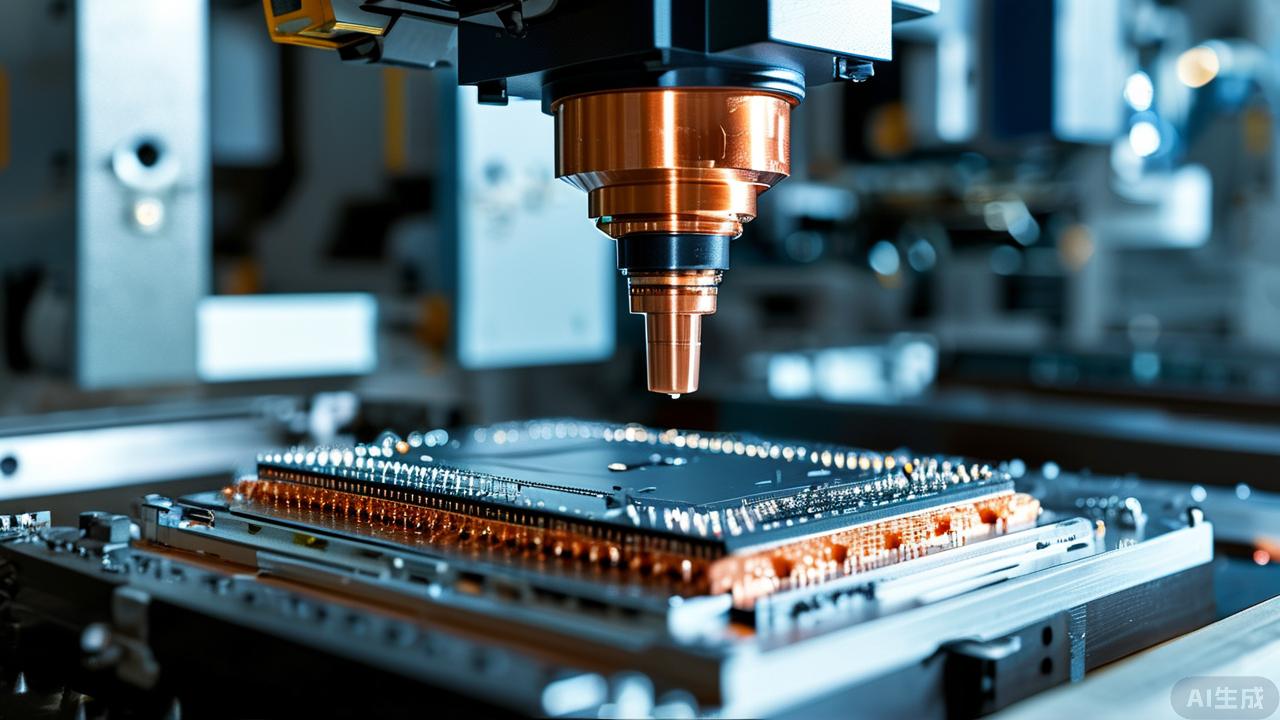

A certain drone startup company once encountered a dramatic turning point: the competitor launch event was advanced by two weeks, and they had to compress the sampling cycle to 24 hours. A certain manufacturer launched a rapid response mechanism overnight, and the engineering team completed the process review within 2 hours after the drawing was confirmed. The high-precision mechanical drill bit completed the drilling operation of 20 layers of boards at a speed of 180000 revolutions per minute. This kind of operation of cutting time into nanoscale is reminiscent of a symphony orchestra conductor precisely controlling the rise and fall of each note. When the circuit board with residual temperature was delivered across three provinces on time, the founder looked at the moment when the surface mount machine started working and sighed, “This is not a simple production, but a technical fantasy played with industrial precision

At a certain smart hardware exhibition, a serial entrepreneur shared his logic of choice: during a sampling process, he requested the manufacturer to etch the team logo in the blank space on the board edge, which exceeded the conventional process requirement and was immediately responded to. Behind this service extension capability is the customer demand database established by the manufacturer, which transforms the special requirements of over 3000 enterprises into callable service modules. Just like a high-end tailor shop that not only provides ready to wear clothing, but also embroiders the abbreviation of the customer’s name on the cuffs, making standardized services a customized texture.

The purchasing director, who has been struggling in the electronic market for 20 years, once calculated that choosing a low price for sampling resulted in a 5% defect rate during mass production, and later maintenance costs exceeded the budget by three times. The stacked structure optimization solution provided by high-quality manufacturers can change the 8-layer board to a 6-layer design without affecting performance, which is a “cost magic” that reduces overall costs by 15%. This reminds people of the famous quote by the architect Gaudi: “Straight lines belong to humanity, curves belong to God.” In the field of circuit board design, exquisite wiring schemes are like a stroke of genius that turns stone into gold.

As the wave of intelligent manufacturing drives the PCB industry towards high-density interconnect boards, leading manufacturers have begun deploying AI assisted design systems. These deep learning models can automatically identify over 200 common design defects, compressing the originally 8-hour engineering evaluation into 20 minutes. A certain automotive electronics customer was surprised to find that the system’s suggested equal length wiring scheme optimized the timing margin by 3 nanoseconds more than the manual design of senior engineers.

In this special field that connects reality and the future, PCB prototyping has already surpassed simple manufacturing processes. It is both a micro demonstration of technological strength and a concrete presentation of business logic. When a 0.6mm thick circuit board passes through twenty precision processes and ultimately carries the countless possibilities of the intelligent world, the copper foil traces hidden under the green oil are silently writing the industrial epic of this era.